TechnoDoc - industrial reporting and analytics

Industrial reporting system for discrete, continuous and hybrid processes

Product overview

TechnoDoc is a system for automated reporting and data analysis, designed for industrial enterprises. It implements data consolidation from automated systems (DCS/MES/ERP) for detailed analysis. TechnoDoc allows to design reports for discrete, continuous and hybrid processes. It could be deployed as a part of WinCC OA project or as a standalone web-application.

Key features:

- DCS/MES/ERP systems data consolidation.

- Complex report templates design.

- Calculation of facilities operation time via custom algorithms.

- Mass and power balances calculation.

- By schedule and by events reports generation.

- Operation as a standalone system or WinCC OA extension.

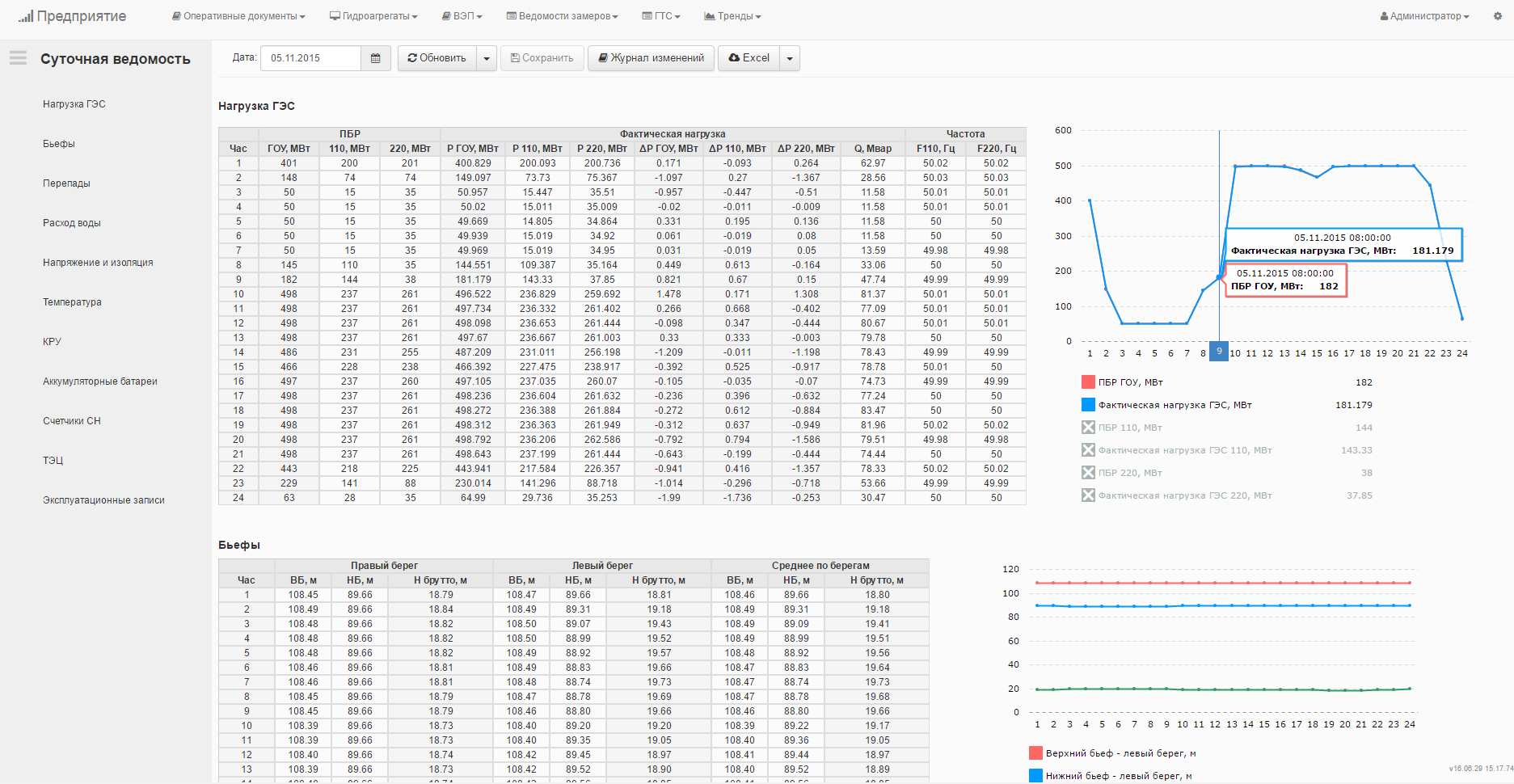

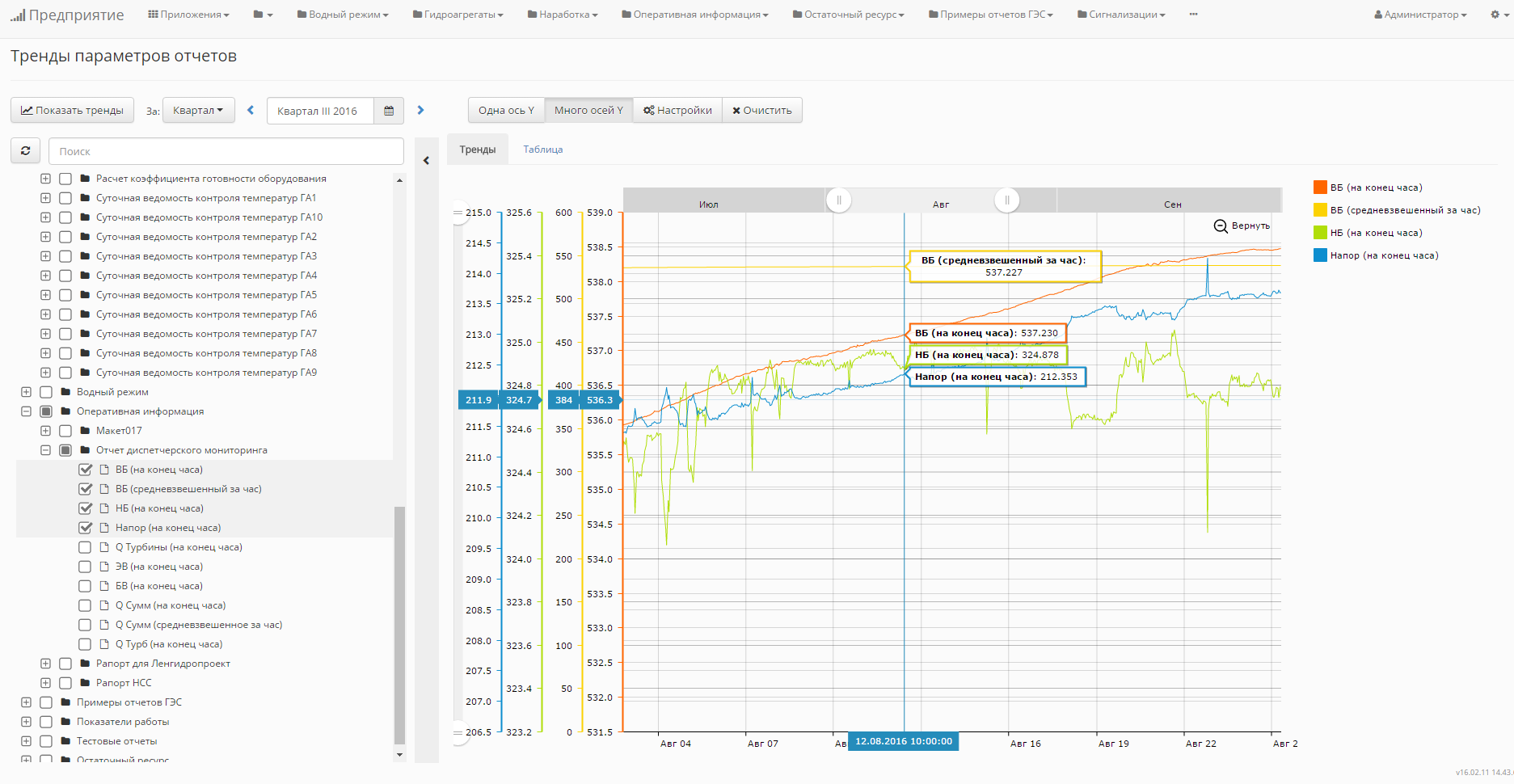

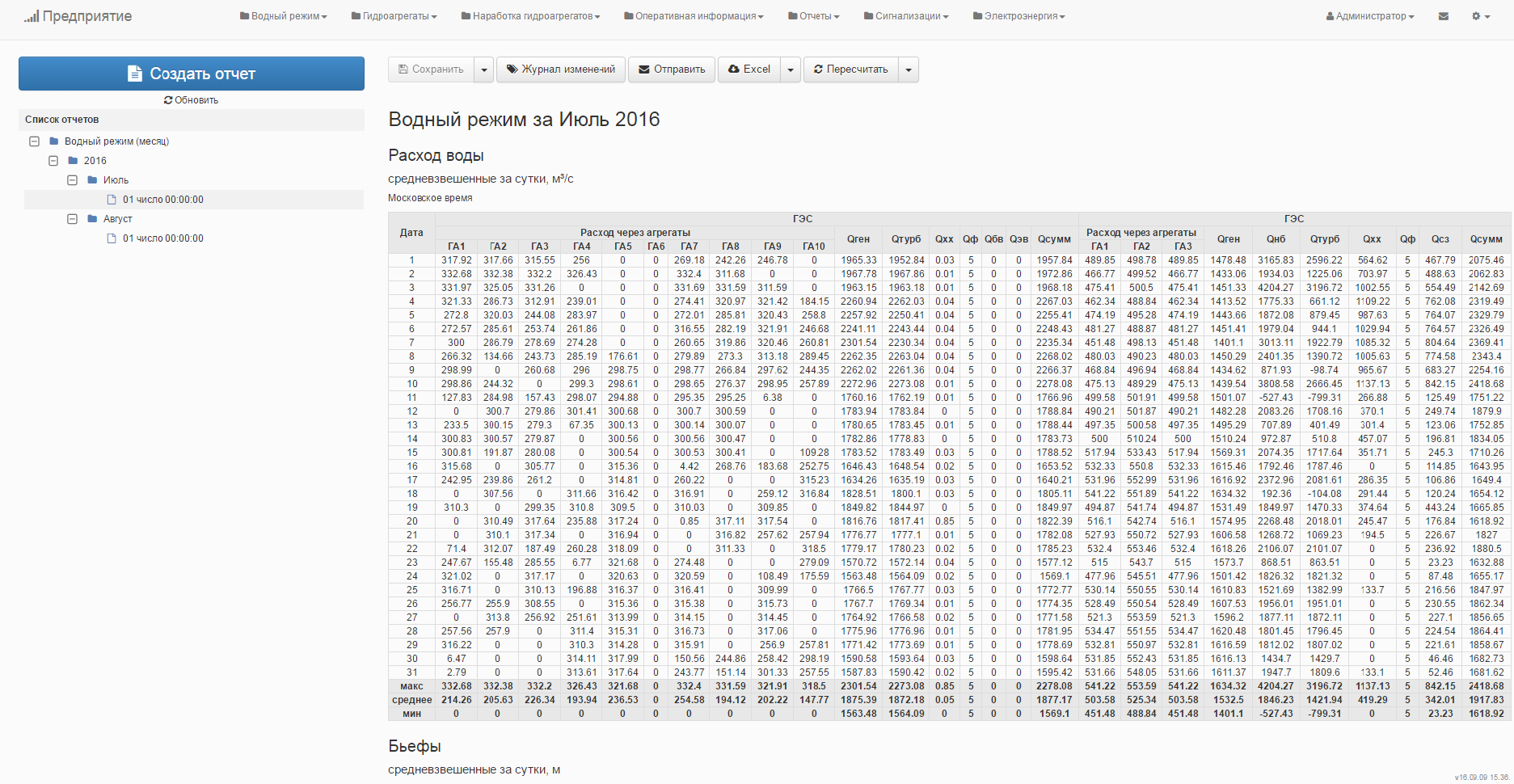

Real-time reporting

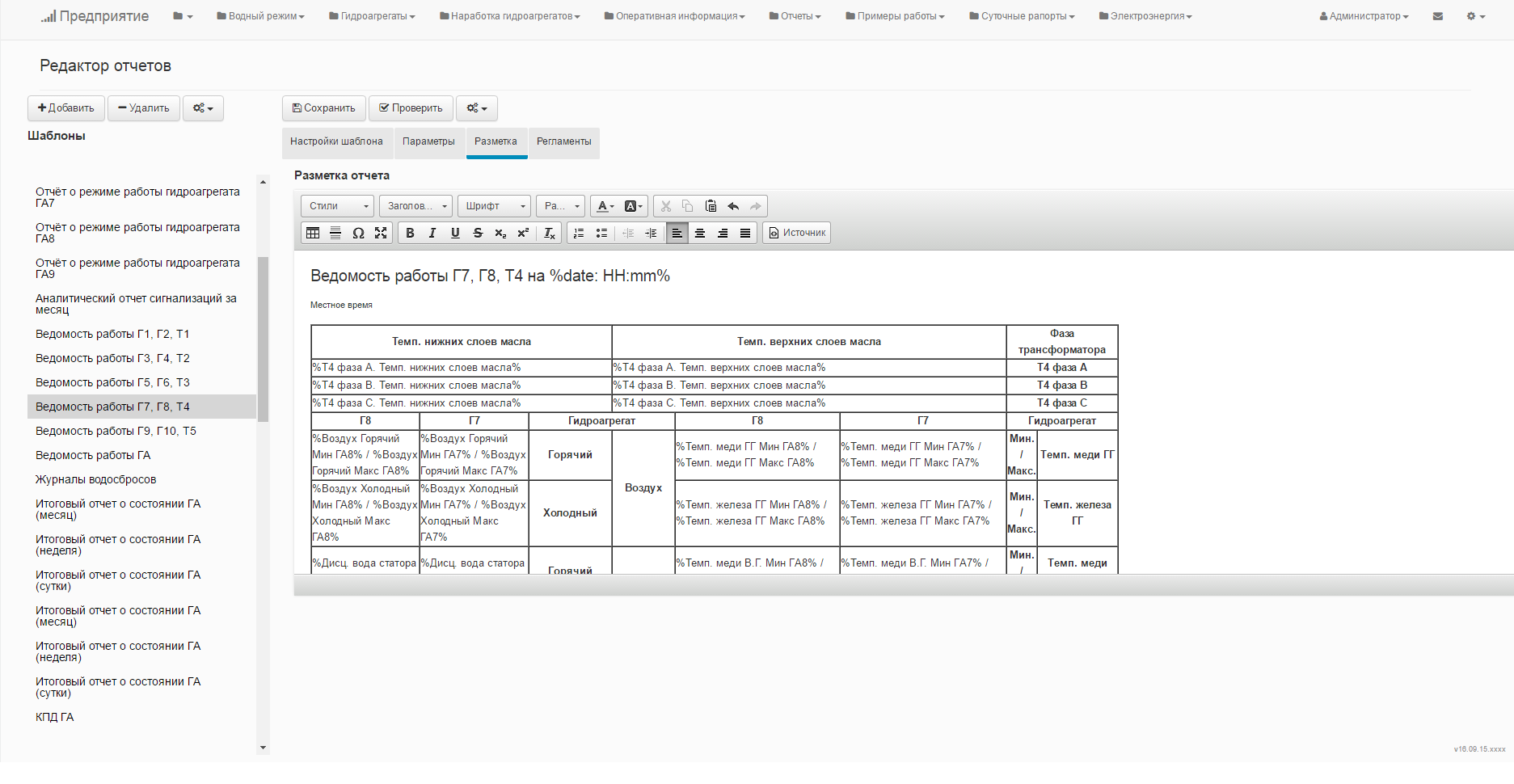

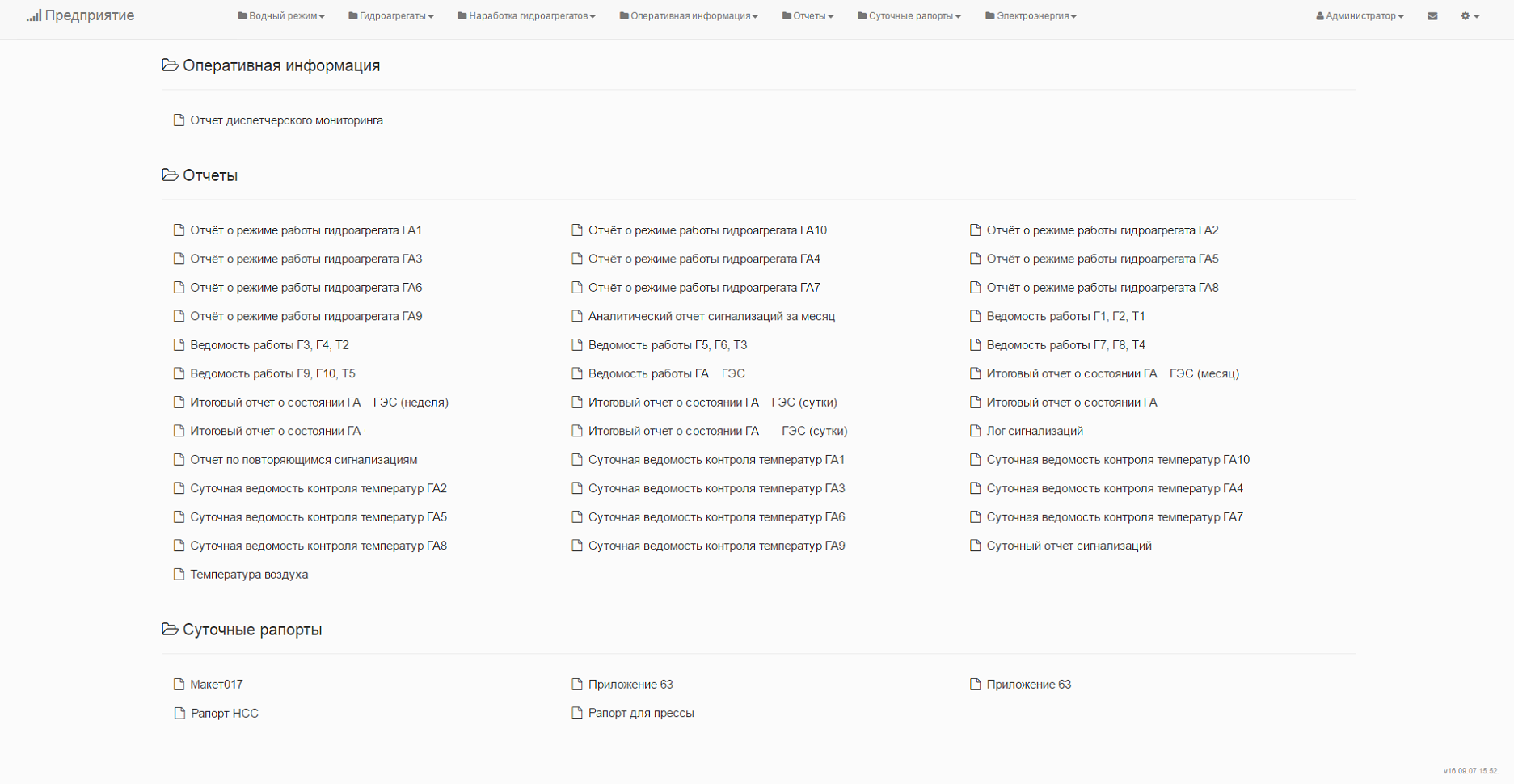

TechnoDoc provides powerful and flexible templates constructor to design reports you need. It uses WYSIWYG web-components, which allows us to create forms with tables, charts and text in a few actions.

The system has a lot of drivers to collect data from enterprise automated systems. The driver is a program connecting to the source and collecting data. Out of the box it is available a set of drivers for industrial protocols (OPC, S7, XMLRPC), Databases (Oracle, MS SQL, MongoDB) and TXT/Excel/CSV files. There is a public API to develop custom drivers as well.

Calculated parameters can also be used. Prepared repository of aggregation functions implements typical calculation such as min, max, avg and many other functions. For more complicated calculations embedded C# compiler can be used. In case of need you can write and check scripts inside the report designer. This approach allows us to calculate the parameters of any complexity.

Features:

- Visual report templates designer.

- Real-time data collecting from external automated systems.

- Manual corrections and changes log for every report.

- Calculated parameters, C# scripts.

- Trends viewer for report parameters.

- Creating reports by scheduling or by events.

- Indicating parameters with bad quality.

- Export PDF/Excel/TXT.

- Sending reports on a schedule by mail.

- Signing reports.

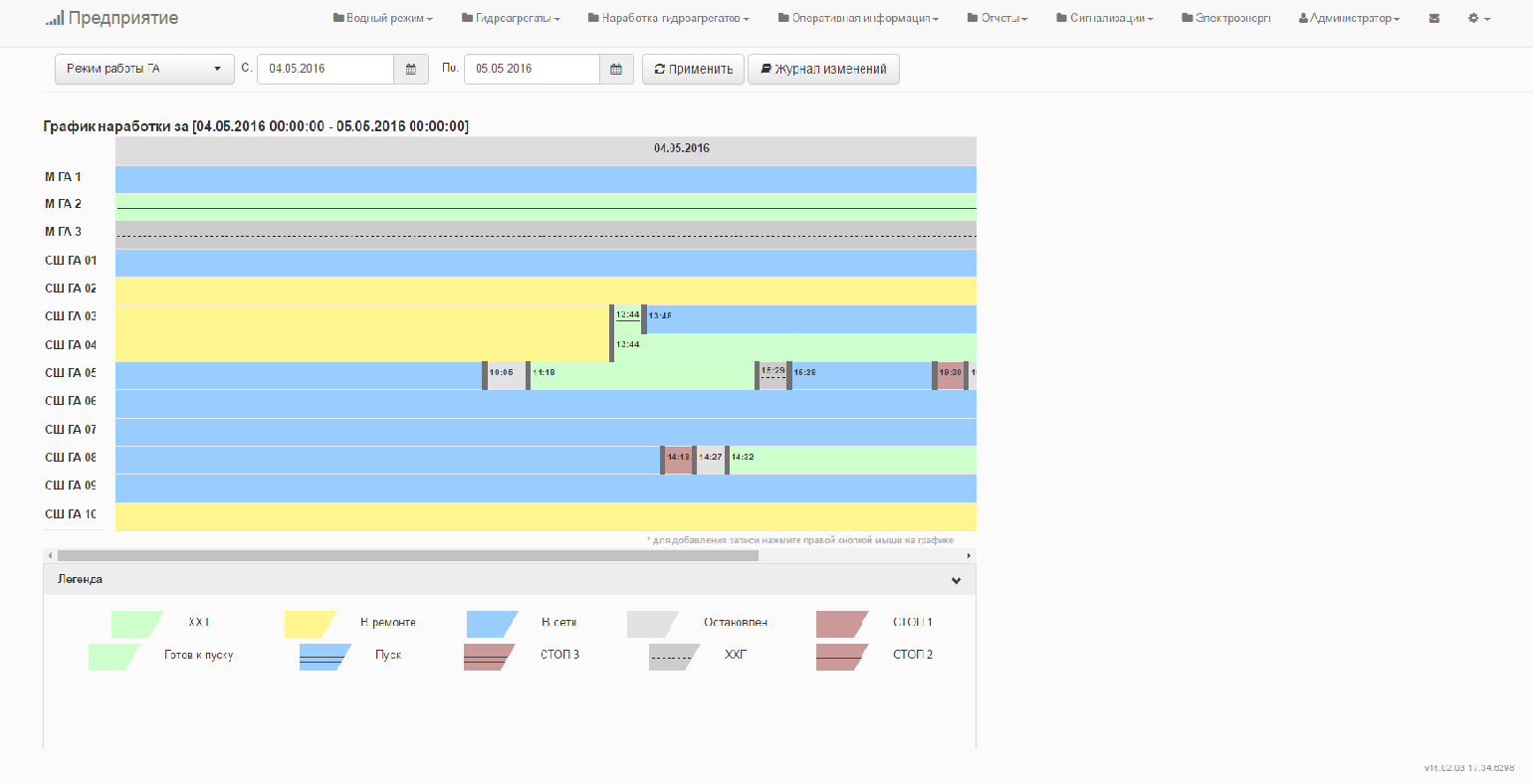

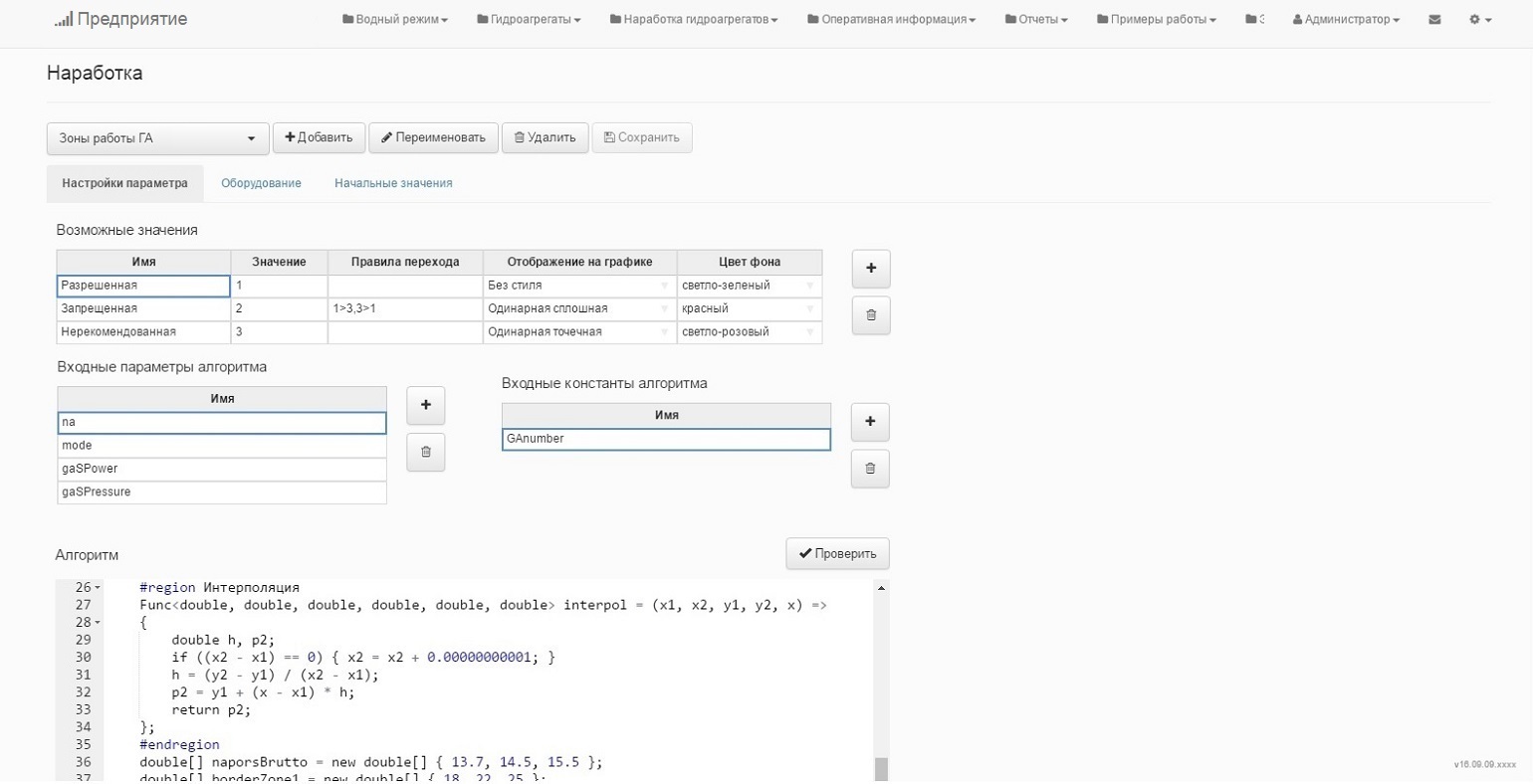

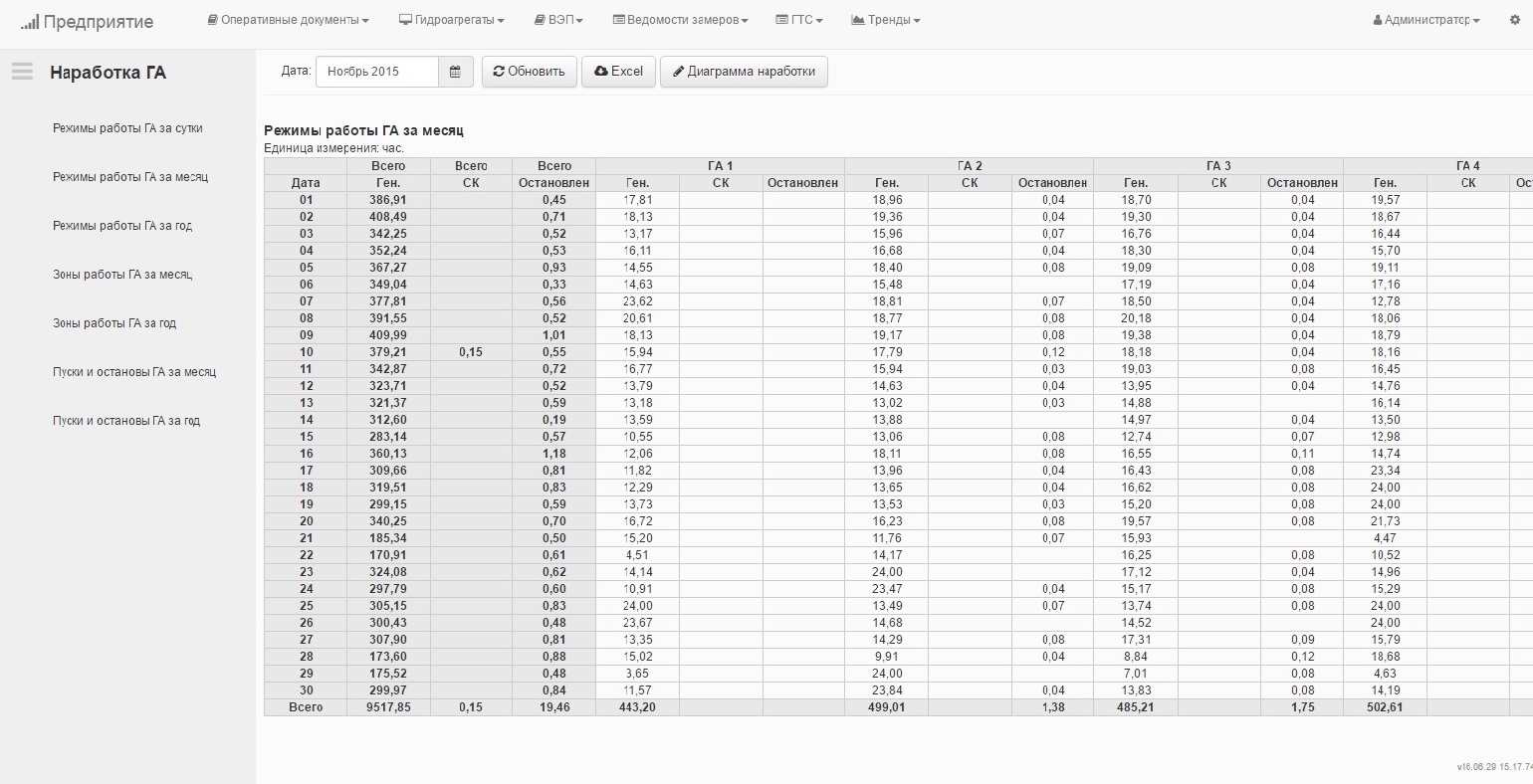

Operation time

The System is able to monitor equipment states in real-time mode. It gives us the answers to the questions - "How long have equipment been working in different operation modes?" and "How often does equipment change operation modes?".

It allows us to know how many times the equipment was started and stopped, how long equipment had been working in limited work areas, etc. Prepared information makes it possible to calculate MTBF, MTTR and OEE indicators in reports.

This flexibility is achieved by the following steps:

- Define a set of equipments and its operation modes.

- Design algorithms to define each possible operation mode in the designer in online-mode.

- Assign input parameters with tags from external automated systems.

Mass and power balances

Accounting of material and electricity balances is an important question for each industrial enterprise. The system allows us to prepare reliable information to find out the broken measuring devices on the plant for calibration and repair.

Features:

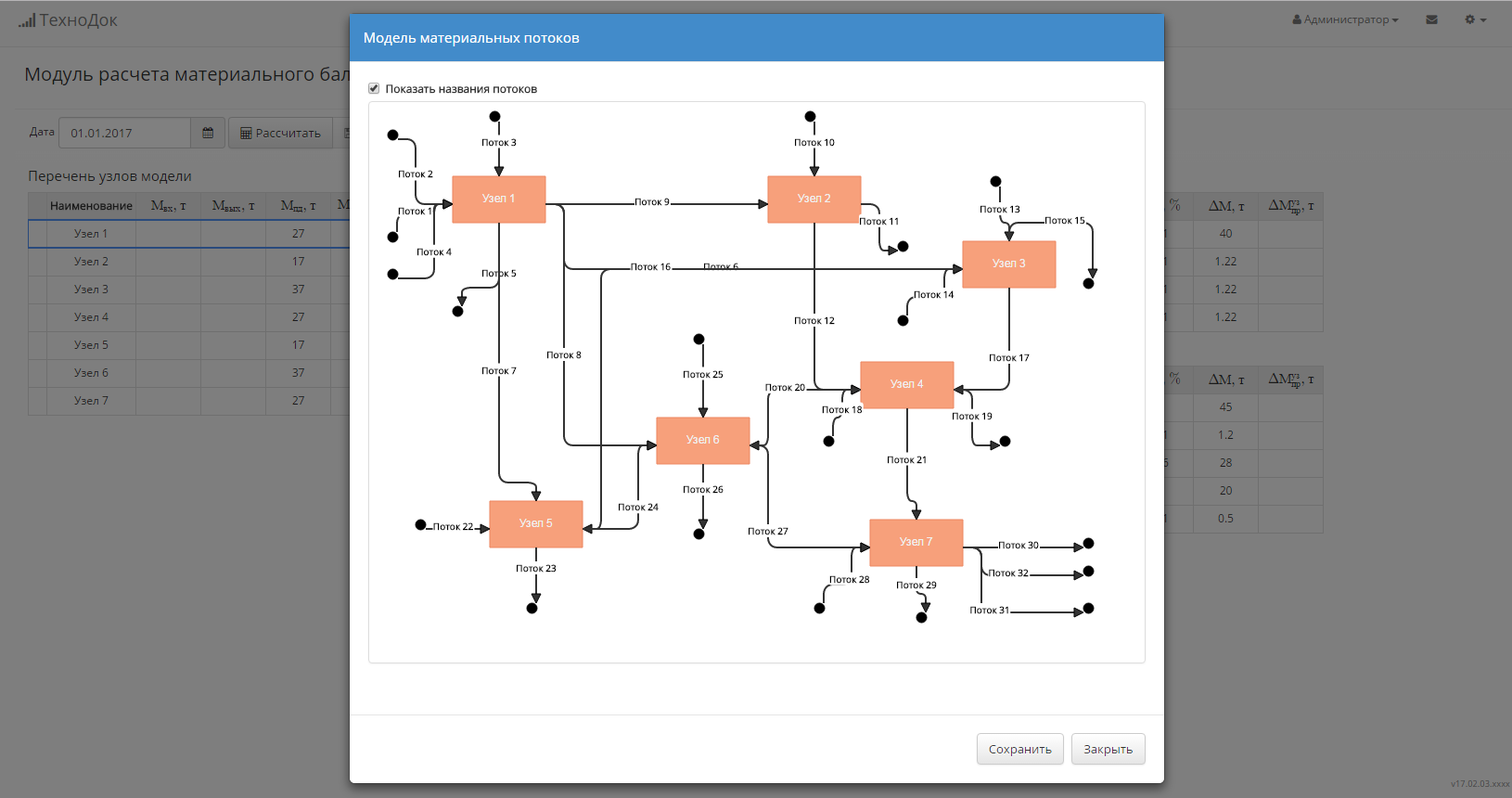

- Creation and maintenance of the material flow model.

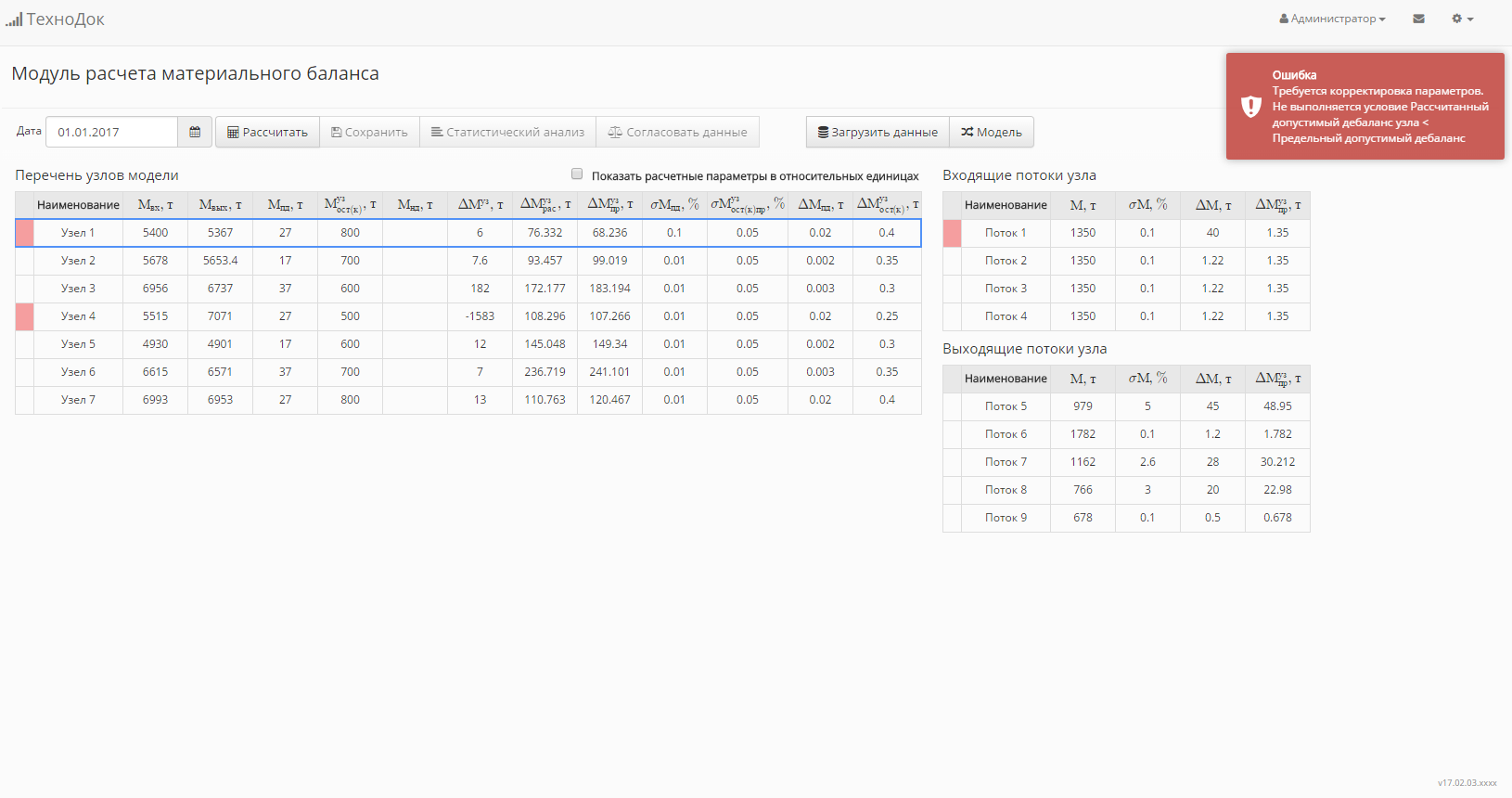

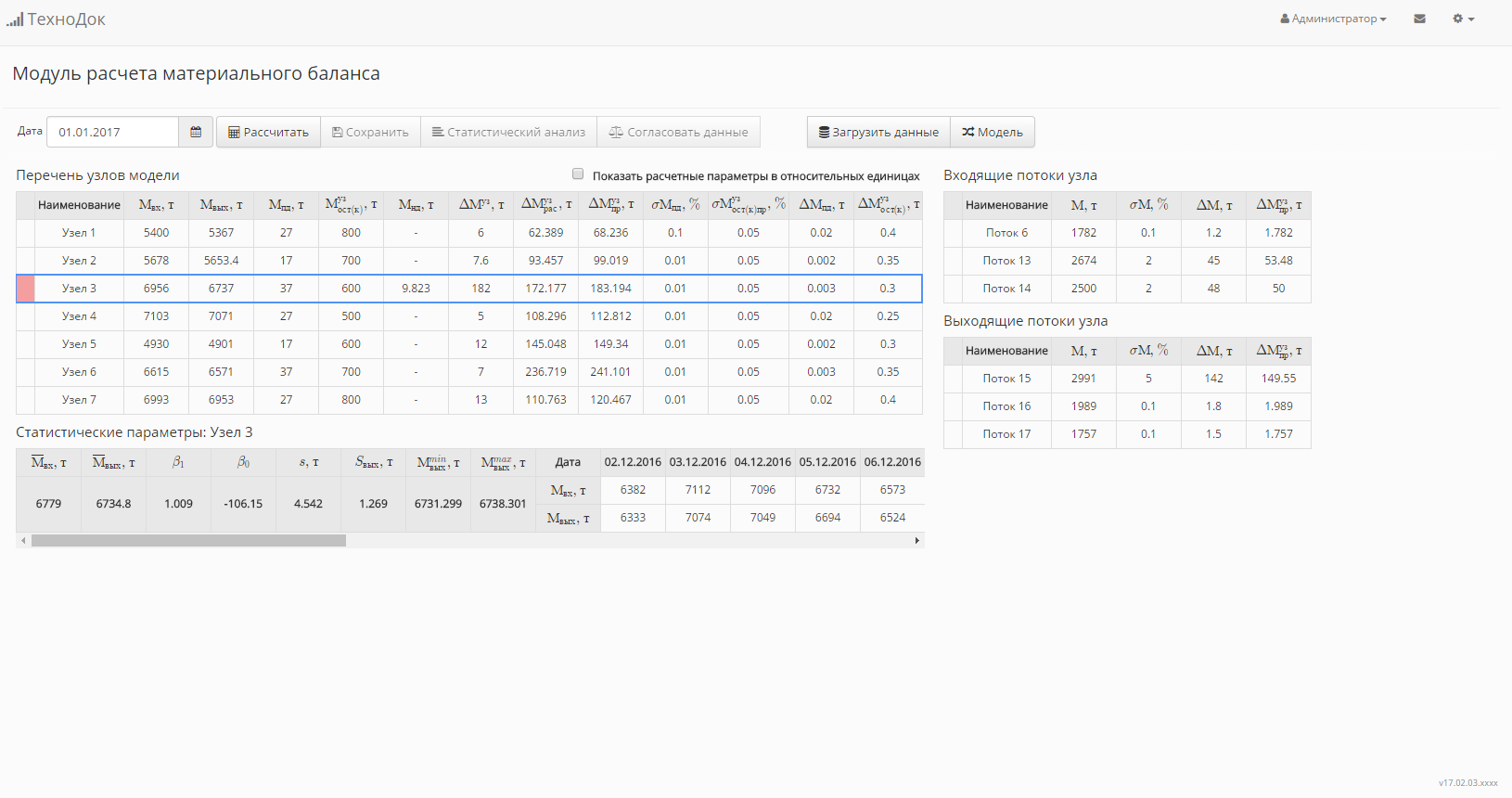

- Detection of measurement errors.

- Determination of the composition of the imbalance for each production facility.

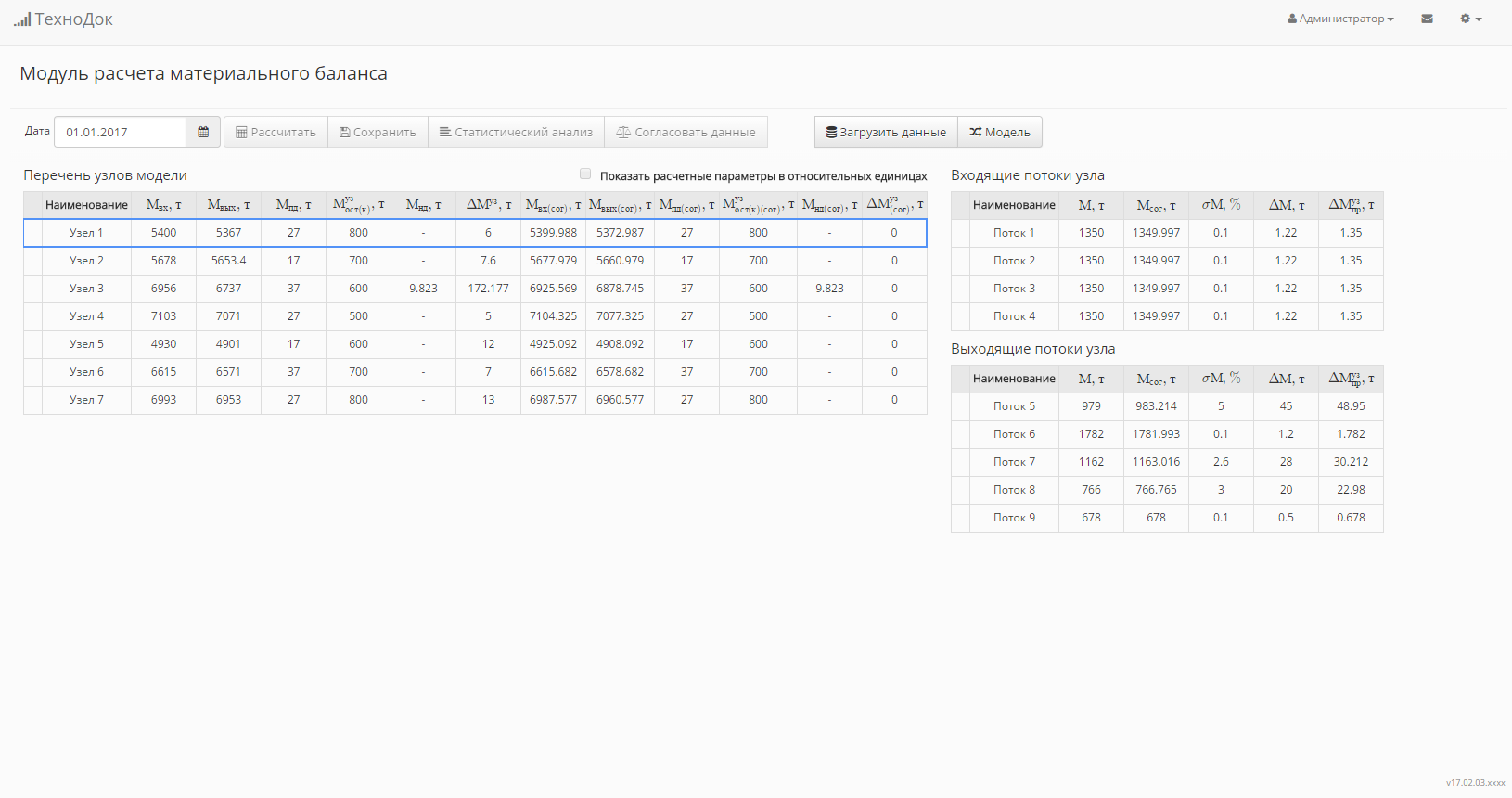

- Calculation of the material balance.

- Preparing of consistent reliable data on balances.

Our experience

SMS-Automation group has rich experience in automating business and reporting workflow processes at energy and petrochemical enterprises.

Video

How to create a new report in WinCC OA \ TechnoDoc

This video shows how to create a new report with tables, charts, calculated parameters and signature in WinCC OA project by using TechnoDoc. The report will be generated on a regular basis every day and will be available for WinCC OA users for viewing and editing.